How It Works!

Step 1: 3D Scan + Design Session (Included)

Every custom splitter starts with a 3D scan of your car. We’ll come to you, scan the front end, and define the splitter’s width, length, and leading edge shape and even tunnel size and spacing to maximise your class regulations. You’ll receive CAD renders to review before anything is built.

We understand that a bespoke carbon splitter is a big purchase! You can book a 3D scan and design session as a standalone service to see the plan before you commit. No strings attached. We credit the full amount toward you splitter if you decide to proceed

→ [Book Your Scan Separately]

Remote or Interstate Clients

If I can’tcome to scan your car, don’t stress! There are workarounds depending on your car and class. Reach out and we will sort the best path forward

Step 2: Approve the Design

You’ll receive CAD renders to review. Nothing gets built until you’re happy.

Step 3: We Build It

The splitter foam core is CNC-cut, laid up with carbon, then vacuum infused with epoxy

- Start time: Based on your place in the queue

- Build time: Around 1.5–3 weeks once production begins

Step 4: Install or Get It Installed

Each splitter includes stainless steel pucks, low profile washers, and M8 bolts to mount the splitter panel itself. If you would like it installed we work with AeroBall Customs (Braeside) or Opulent Garage (Epping).

Mounting brackets and support rods are not included.

You have two options:

• Professional Awesome quick release system: We can supply the brackets and rods. Budget $350 to $500 AUD depending on setup. You pay the kit cost only and we cover international shipping from the United States.

• Custom fabricated solution: Use your trusted metal fabricator.

Step 5: Carbon Airdam Add On (OPTIONAL)

Done for you: We can supply and install a carbon airdam shaped to your bar or lip for $800 AUD. This is done after the splitter is fitted, so the car must be dropped off with the splitter already installed.

Supply only: If you or your trusted installer want to do the fitment, we can supply an extra long carbon strip for you to bond or rivet in. $350 AUD

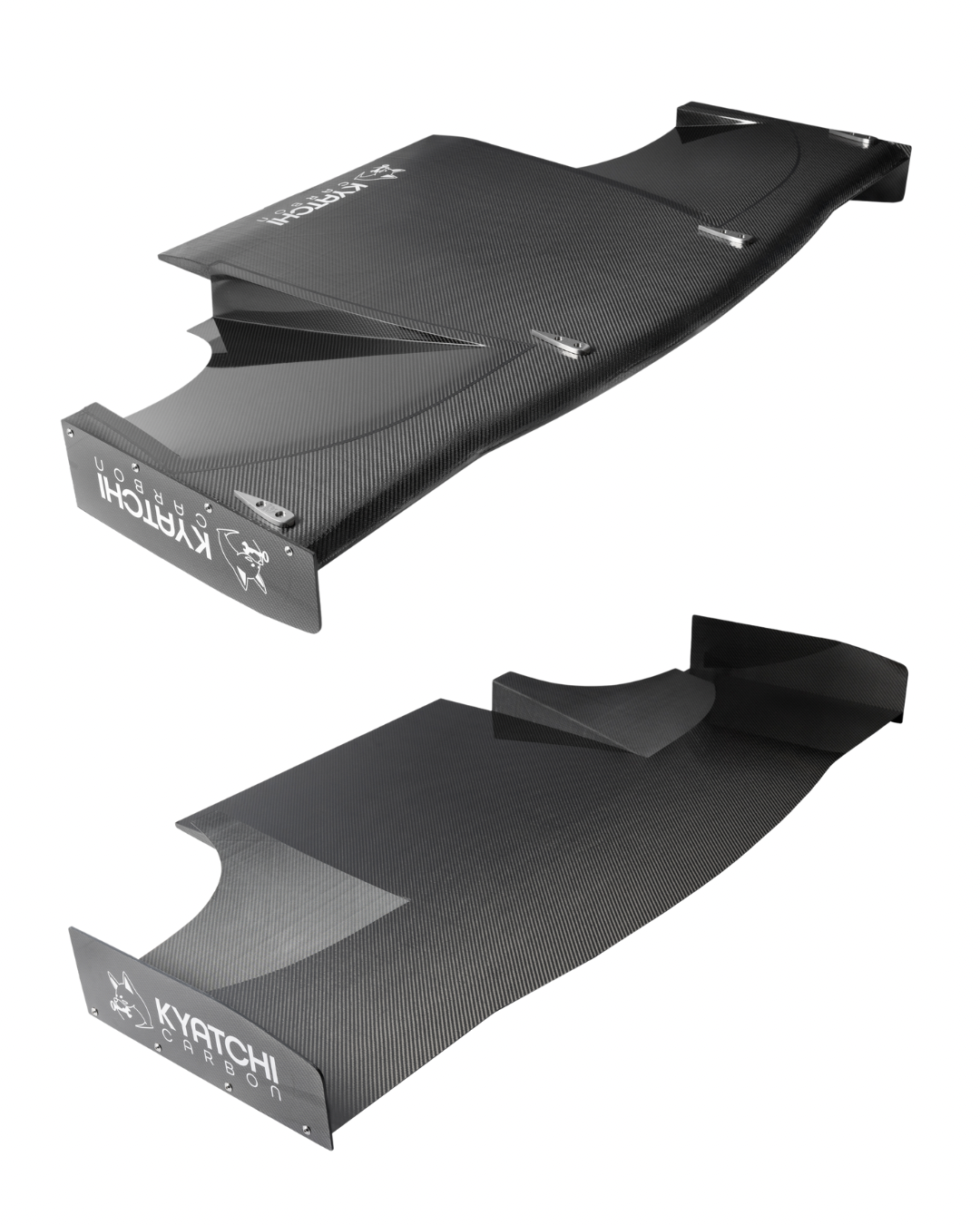

Which Splitter Matches Your Car’s Setup?

| Variant | Front Load @ 250 km/h | Aero Efficiency (L/D) | Build Time* | Install Difficulty | Best With |

|---|---|---|---|---|---|

| Base Splitter | 213 kg | 8.1:1 | 1-2 weeks | Moderate | Standard rear wing |

| + Endplates | 340 kg | 11.7:1 | 1.5-2.5 weeks | Moderate | Large rear wing |

| + Endplates + Tunnels | 411 kg | 13.0:1 | 2-3 weeks | Advanced, may require trimming and more complex mounting | Dual element rear wing |

* Build times begin once design is confirmed.

All tests were performed at 1.0° nose down rake for the base splitter and endplates, and at 0.5° rake for the configuration with tunnels and endplates.

Data reflects a splitter size between Clubsprint and Open Class. The base splitter was tested at a slightly smaller area than the endplate variants, which used a larger footprint to fit the plates. Results reflect those exact configurations and are not area normalised.